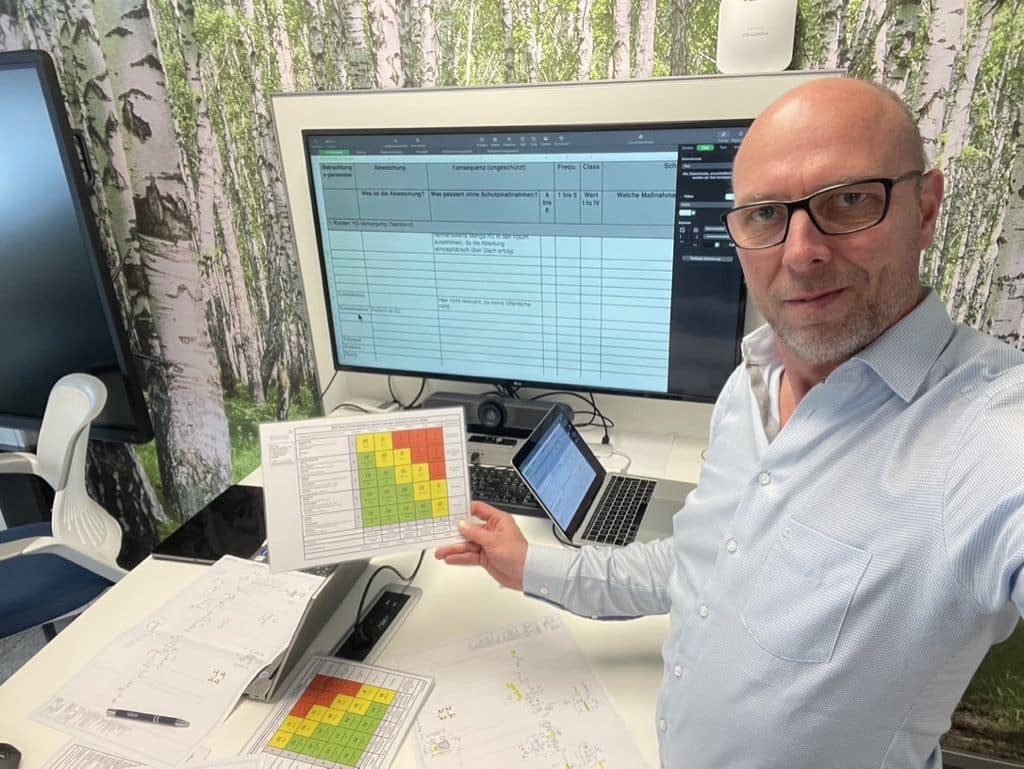

HAZOP analysis with AI support

In the year 1999, Christian Machens developed the world’s first fuel cell boat, the Hydra, and thereby laid the foundation for innovations that will extend far into the future. Now, 25 years later, he is once again setting standards in the technology landscape – this time with a world first that has the potential to fundamentally change the safety analysis of systems.

In modern technology, carrying out a HAZOP (hazard and operability) analysis is essential for systems with high risk potential. This analysis is carried out by a team of experienced engineers under the leadership of a “HAZOP chair” to identify possible dangers in systems such as fuel cell or electrolysis systems and to develop suitable countermeasures. In Germany this is also referred to as PAAG, which precisely describes the process of recognizing dangers, assessing their effects and determining countermeasures.

Traditionally, the role of the HAZOP chair requires not only technical know-how, but also strong social skills. The trick is to use imagination and experience to extract all critical scenarios from the discussions and document them in a structured form. In this, not only is the dangerousness of the scenarios assessed, but also their probability of occurrence, in order to ultimately create a ranking of the risks and requirements for the reliability of the countermeasures.

But how safe is it to leave security-relevant decisions to an AI (artificial intelligence)? “It’s not about handing over safety responsibility to a machine, but rather about simplifying repetitive tasks,” stresses Machens.

“I would like to pass on the expertise in the field of explosion protection and hydrogen that I have accumulated over the last decades to an artificial intelligence. AI is already used in many areas today, but it has not yet been used to support HAZOP analyses.”

Christian Machens

Procedure

In a typical HAZOP meeting, up to eight engineers discuss various aspects of a system over several days, from gas and cooling water loops to the reliability of the power supply and specific dangers for people in the vicinity of the system. These meetings are not only time-consuming and costly, but also stressful for those involved. In addition, the experience of the participants significantly influences the result.

Typically, a HAZOP is performed when the P&ID (piping and instrumentation diagram) of a facility is completed. This is where the new, intelligent software comes into play. It analyzes the existing information, detects weak points in the system and automatically suggests measures to eliminate them.

The real world first is that the AI recognizes and analyzes the P&ID, which is usually available as a DXF or DWG file, and then automatically fills in the associated HAZOP table. This process saves those involved many hours of work and makes the work much easier.

“It is important to understand that AI is not replacing humans. The responsibility for the safety of the system always remains with people. But the system can significantly simplify the paperwork, speed up the process and save costs,” according to Machens. In addition, the AI system has knowledge of essential legal principles, such as EN and ISO standards as well as DGUV and TRGS regulations. This makes it possible to offer “just in time” compliant solution suggestions during the HAZOP.

For implementation of this groundbreaking idea, Machens received financing from the bank Sächsische Aufbaubank (SAB), which underlines the economic potential of this development. The development of the AI system is being carried out in collaboration with MOVE Technology GmbH, an experienced company in the field of AI development.

“I am currently training several AI models so that they can correctly recognize the individual components in the P&ID and understand their interaction. The next step is the performance of a full HAZOP analysis,” states Machens.

Presented at the 18th Explosion Protection Days

The results of this development were presented on September 24, 2024 as part of the 18th Explosionsschutztage (Explosion Protection Days) at the Haus der Technik in Essen. The AI system “HAZOP-KI” will next be further tested and optimized in a large engineering firm that plans exhaust gas treatment and hydrogen systems. The system will soon be available to other interested users with a monthly license.

“Of course, the question of data security also arises,” stresses Machens. “The AI is installed and operated directly on the servers of the respective users. This way, sensitive data always remains in the hands of the user.”

In summary, this development is a valuable tool for engineering offices, certification bodies, insurance companies and operators of safety-critical systems. An AI cannot replace humans. However, it offers excellent support when carrying out HAZOP analyzes and can also be of important help to less experienced engineers.